- info@zendoori.com

- Open Hours: Mon - Fri 9:00 - 18:30

- +86 13858942009

At Zendoor, we are dedicated to revolutionizing the way you think about doors. As a premier manufacturer of high-quality Wood Plastic Composite (WPC) doors, we combine the natural beauty of wood with the durability and sustainability of recycled plastics. Our doors are designed to withstand the test of time, making them a perfect choice for both residential and commercial applications.

Founded on the principles of innovation and sustainability, Zendoor is committed to providing eco-friendly door solutions that do not compromise on quality or aesthetics. Each door from our collection is crafted with precision and designed to enhance the beauty and functionality of any space.

Zendoor doors are known for their exceptional resistance to weather, water, and wear, ensuring that they remain a durable and attractive feature of your property for years to come. Whether you are looking for a stylish entrance door, a practical interior door, or custom solutions, Zendoor has the expertise and the products to meet your needs.

Experience the perfect blend of form and function with Zendoor, where your satisfaction is our priority.

Excepteur sint occaecat cupid atat non proi dent, sunt in culpa qui officia dese.

Excepteur sint occaecat cupid atat non proi dent, sunt in culpa qui officia dese.

Excepteur sint occaecat cupid atat non proi dent, sunt in culpa qui officia dese.

Excepteur sint occaecat cupid atat non proi dent, sunt in culpa qui officia dese.

Standard

Mechanical Properties:

Environmental Resistance:

Safety Standards:

Environmental and Health Standards:

Aesthetic and Functional Standards:

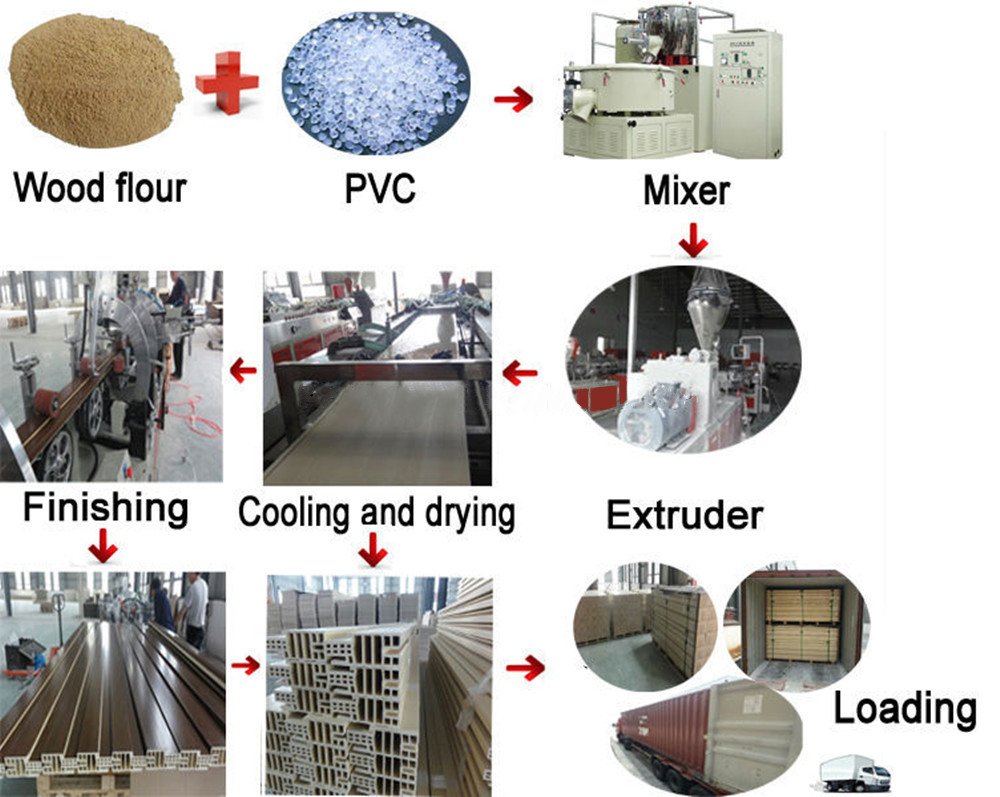

Material Preparation:

Extrusion:

Cutting and Trimming:

Assembly:

Finishing:

Quality Control:

Packaging and Shipping:

Raw Material Inspection:

Production Monitoring:

Product Testing:

Dimensional Checks:

Safety and Compliance Testing:

Final Inspection and Packaging:

Continuous Improvement:

。

QUESTIONS & ANSWERS

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

any problem feel free contact with us!

SUBSCRIBE NEWSLETTER

"At Zendoor, we pride ourselves on delivering high-quality, customizable WPC doors to meet the unique needs of our B2B clients worldwide."

Zendoor guarantees top-notch quality in every WPC door we produce.

2024 Zendoor. All rights reserved.

WhatsApp us